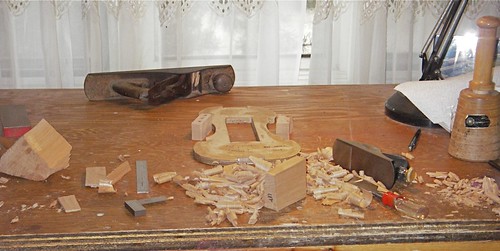

After laying out the lines of the neck and scroll in pencil, I start cutting away some of the excess wood. Note that the peg-holes are drilled prior to this, while the neck is still square. Here the saw is nearly done cutting the bass-side of the peg-box. It has already cut the wood from the treble side, and the gouge and rasp cleaned out the stuff. You can see the gap on the side next to the bench. It sure is handy having handtools that can work on their own with minimal direction! :-)

Here we have the first turn in the scroll rough cut and chipped out. I then use the rasp, looking from side to side, trying to get things even. I'll call it a day, and finish up the rest later.