Friday, October 25, 2013

Soundposts and craftsmanship

Cheap fiddles have been sold as long as fiddles have been sold. The customers are the poor or uneducated. It looks like a violin. I want to see if I like it before I spend much. The usual story we've all repeated when trying to save some money on something.

One came into the shop the other day. "Doesn't sound so good," was the complaint. Actually, "sounds really bad" was the complaint. The e-string was unbearable. Starting off with bad equipment is an easy way to answer the question "will I like it?", but that's part of the education angle.

Here's what the soundpost looked like.

This was how it was sold by a music store in the area -- a starter fiddle -- and at least implied that it was a product ready-to-go. It was not. Note the minor contact of the soundpost with the back. Not only will this prove less than optimal in tone, it is also dangerous for the instrument. Over time, this can create a crack in the back. Once a back-crack occurs on an instrument like this, it's all over. Out it goes with last week's garbage.

This factory-installed soundpost had badly cut bevels -- I actually doubt much thought was given to them at all -- and the post overall was too short.

We put a new one in.

We replaced the strings as well, the factory strings being only decorative. I probably shouldn't use the word 'decorative' that way.

It sounds much better now. Never going to be great, but at least it is essentially firing on all cylinders The owner might actually grow to like playing the fiddle.

Labels:

back,

repairs,

soundpost,

Student instruments,

violin repair

Wednesday, September 18, 2013

Student cello repair

This time of year, I see instruments from the local schools that need repair. This is a cello from a middle school. It's been around for years. The label is a photocopy of a Juzek label, and I never know what to think of these. They are common, and I don't know if the Juzek factory did this, or if it's a knock-off. It's not a bad little cello, but it's seen a lot of abuse from middle-school students, which, of course, is one way these students learn.

This cello has had many repairs, including having the top off. This is a fitted patch for a rib crack. Reasonable, if a little thick. I left well-enough alone.

Here is a soundpost patch, nicely done, though with some later damage due to improper soundpost position, and a diamond-shaped cleat to help hold the crack. I suspect the diamond cleat was added without taking the top off, with a clamp through the f-hole, and whoever did it didn't realize there was already a soundpost patch in place.

Here are pyramidal cleats put in on a rib crack, done through the outside. The little 'doughnuts' actually serve to hold a thread. In this method of repair, a hole is drilled through the ribs for each cleat, a wire or thread run through the hole and wiggled out the f-hole, the cleat is then run through it, with the ring to hold it tight. Glue applied to the rib-side surface, it is then pulled back into place against the rib and tied into place until the glue dries. Not recommended. All of these cleats were loose. I removed them and recleated with linen.

So, is this cello worth this amount of repair? Probably not, but I am not charging full rate. I hope it is some contribution to the orchestra program in my area, and that some student will perhaps learn to love playing the cello. At the very least, we will get a few more years out of this little (3/4) cello, and it is actually far nicer than many of the newer 3/4 cellos I've seen in recent years. Many of those are complete junk.

This cello has had many repairs, including having the top off. This is a fitted patch for a rib crack. Reasonable, if a little thick. I left well-enough alone.

Here is a soundpost patch, nicely done, though with some later damage due to improper soundpost position, and a diamond-shaped cleat to help hold the crack. I suspect the diamond cleat was added without taking the top off, with a clamp through the f-hole, and whoever did it didn't realize there was already a soundpost patch in place.

Here are pyramidal cleats put in on a rib crack, done through the outside. The little 'doughnuts' actually serve to hold a thread. In this method of repair, a hole is drilled through the ribs for each cleat, a wire or thread run through the hole and wiggled out the f-hole, the cleat is then run through it, with the ring to hold it tight. Glue applied to the rib-side surface, it is then pulled back into place against the rib and tied into place until the glue dries. Not recommended. All of these cleats were loose. I removed them and recleated with linen.

So, is this cello worth this amount of repair? Probably not, but I am not charging full rate. I hope it is some contribution to the orchestra program in my area, and that some student will perhaps learn to love playing the cello. At the very least, we will get a few more years out of this little (3/4) cello, and it is actually far nicer than many of the newer 3/4 cellos I've seen in recent years. Many of those are complete junk.

Wednesday, June 19, 2013

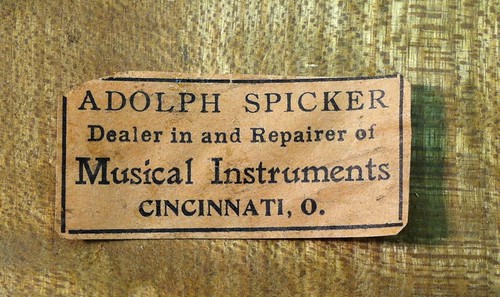

Adolph Spicker

Pulled the top off a violin today, and found this little repair label glued to the rib near the end-block. It's about 3/4" by 3/8", and came loose from the rib, being photographed here against the inside back. After getting my work done, I glued it back in place.

It reads: ADOLPH SPICKER, Dealer in and Repairer of Musical Instruments, Cincinnati, O.

I hadn't heard of Adolph Spicker, but did a quick internet search. I found this news story from March 17, 1928.

ADOLPH SPICKER DIES

Friends of Adolph Spicker, aged 60, of Cincinnati, Ohio, last week were shocked to hear of his death, which occurred at his home on Friday. He was proprietor of a violin store and repair shop in Cincinnati and numbered among his clients Ysaye, Kriesler, and MacMillen. He received his musical education in Germany.

Friday, May 24, 2013

Glasgow Kit Fiddle

For some time, I've wanted to build a kit fiddle, aka pochette or dance master's fiddle. Just never got around to it. A kit fiddle, as I understood it, was primarily used by dance masters as they gave instruction in the homes of the well-off. This was the way people learned the dances, in order to show proper education at those formal public events. The National Music Museum has a nice photo display of pochettes, including this of one in action.

These things are tiny, say 15 inches or so, and not meant to put out much volume -- a tool for a job, one that isn't done much these days.

Last month, Rachel Barton Pine put on a concert of Vivaldi's Four Seasons with the Boise Baroque Orchestra. In conjunction with that, she gave a talk on Baroque performance techniques, which I also attended. During the talk she made two points regarding kit fiddles that caught my ear. First, these were also used as traveling fiddles. Most taverns had a violin for use by customers, and since it was hard enough to travel in those days, it would be an additional chore to carry along a full-size instrument. But travelers might want to play a few tunes, so these pochettes, with their small bows and small cases, could be taken along to while away the idle time.

This also struck me, having just returned from a trip where I took my full-sized fiddle, case, and bow, and then ended up putting a heavy practice mute on it to while away the random spare time in the motel room, learning a few new tunes with my iPhone headphones on. I'm traveling to see things, and the violin is nice to have along, but I'm not performing. Something smaller to carry, particularly when flying, would be convenient.

The second thing Mrs Pine mentioned that caught my ear was that while idling away the hours, these travelers developed, or improved, their strathspey bowing. I'm still not sure how, but since I am involved with Scottish Country Dance, that was interesting to me.

So, I started looking through my collected materials and that on the web. I wanted a simple design, as this was a concept to be tried, and I didn't want to get bogged down in decorative details. I settlled on the Glasgow Kit Fiddle --

I had no dimensions for this instrument, but decided to go with a 3/4 violin string length and scale from that to the size of the photo. I drew out a pattern and cut a simple plywood form.

I should add that since I was being simple, I decided also to be cheap. All the material I used, except the fingerboard and the ribs, were scrap I had lying about the shop -- discarded other projects.

The neck I cut from a block of local maple, roughly at the right orientation.

The ribs I bent in one piece. Not sure that was a great idea, but that's what I did this time.

When I was done, I had a kit fiddle with a total length of just under 20 inches. Here it is next to a 1/4-size violin bow.

These things are tiny, say 15 inches or so, and not meant to put out much volume -- a tool for a job, one that isn't done much these days.

Last month, Rachel Barton Pine put on a concert of Vivaldi's Four Seasons with the Boise Baroque Orchestra. In conjunction with that, she gave a talk on Baroque performance techniques, which I also attended. During the talk she made two points regarding kit fiddles that caught my ear. First, these were also used as traveling fiddles. Most taverns had a violin for use by customers, and since it was hard enough to travel in those days, it would be an additional chore to carry along a full-size instrument. But travelers might want to play a few tunes, so these pochettes, with their small bows and small cases, could be taken along to while away the idle time.

This also struck me, having just returned from a trip where I took my full-sized fiddle, case, and bow, and then ended up putting a heavy practice mute on it to while away the random spare time in the motel room, learning a few new tunes with my iPhone headphones on. I'm traveling to see things, and the violin is nice to have along, but I'm not performing. Something smaller to carry, particularly when flying, would be convenient.

The second thing Mrs Pine mentioned that caught my ear was that while idling away the hours, these travelers developed, or improved, their strathspey bowing. I'm still not sure how, but since I am involved with Scottish Country Dance, that was interesting to me.

So, I started looking through my collected materials and that on the web. I wanted a simple design, as this was a concept to be tried, and I didn't want to get bogged down in decorative details. I settlled on the Glasgow Kit Fiddle --

I had no dimensions for this instrument, but decided to go with a 3/4 violin string length and scale from that to the size of the photo. I drew out a pattern and cut a simple plywood form.

I should add that since I was being simple, I decided also to be cheap. All the material I used, except the fingerboard and the ribs, were scrap I had lying about the shop -- discarded other projects.

The neck I cut from a block of local maple, roughly at the right orientation.

The ribs I bent in one piece. Not sure that was a great idea, but that's what I did this time.

When I was done, I had a kit fiddle with a total length of just under 20 inches. Here it is next to a 1/4-size violin bow.

Still learning how to play the thing, and plan to put up a video soon. If you'd like to see more details of the construction, you can go to my Flickr set (assuming the new format allows such a thing).

Thursday, May 23, 2013

Peg-box crack

Here's a view of the treble side of a more-or-less typical early-20th-century factory fiddle.

When looking at a used/vintage fiddle with the idea of purchase, this is a good area to examine closely.

Note the little bent "line" near the far-right peg hole. Look closer.

This is a crack, and it's a crack that would put me off purchasing the instrument unless there were some other highly attractive parts that would make the cost of repair worth it. This type of crack needs serious repair, not just a simple glueing.

It's probably the most common location for a peg-box crack, on the A-peg of a violin (or the D-peg of a viola or cello), because often the grain runs out towards the carved edge. This one is a bit unusual, in that the grain is twisty here and the crack follows that twisty grain. Often, it is a straight crack, following the straight-grain of the pegbox.

I'll have to talk to the customer to see what they want to do with this. It can be repaired. Simply a matter of worth and value, which needs some thought.

When looking at a used/vintage fiddle with the idea of purchase, this is a good area to examine closely.

Note the little bent "line" near the far-right peg hole. Look closer.

This is a crack, and it's a crack that would put me off purchasing the instrument unless there were some other highly attractive parts that would make the cost of repair worth it. This type of crack needs serious repair, not just a simple glueing.

It's probably the most common location for a peg-box crack, on the A-peg of a violin (or the D-peg of a viola or cello), because often the grain runs out towards the carved edge. This one is a bit unusual, in that the grain is twisty here and the crack follows that twisty grain. Often, it is a straight crack, following the straight-grain of the pegbox.

I'll have to talk to the customer to see what they want to do with this. It can be repaired. Simply a matter of worth and value, which needs some thought.

Thursday, May 2, 2013

Thursday, March 7, 2013

Top arching.

Just an in-progress shot, complete with messy bench; I'm waiting for a customer to show up with a bass that's lost its neck and another with a couple fiddles that need some tending-to.

The top is at the point I really need to finish the outline, get the corners into shape, and get the purfling installed. This spruce is really chippy, so I have the wet-stone at the ready for sharpening touch-ups. I'm using an Bros. Amati outline and Strad "Titian" arching.

Tuesday, March 5, 2013

Idaho at 150.

150 years ago yesterday, President Lincoln signed into being the Idaho Territory. The Idaho Historical Museum put together an exhibit in honor of this, "150 Things that Make the Gem State Unique." Tim and I were asked to wander about during the Friends of the Museum opening last night, playing a few tunes. We're always delighted to play at the Museum -- a favorite spot.

Just playing whatever came into our heads, we did manage to get into the Boise paper, the Idaho Statesman --

One of the local TV stations caught us, too. We're only on film for a brief moment, though our music keeps going. I'm unaccoustomed to having a TV camera filming me while I play, and spent some energy trying not to make too many weird faces. Had I known it would be used for background music, I would have relaxed a bit! :-) Here's a link to the piece.

The fiddle here is the one I described building in posts throughout last summer and fall.

Just playing whatever came into our heads, we did manage to get into the Boise paper, the Idaho Statesman --

The fiddle here is the one I described building in posts throughout last summer and fall.

Friday, February 8, 2013

labeled Klotz 1760-ish.

This one is owned by a retired fellow, who has had it for some time. I don't know if it is what it reports to be, Egidius Klotz 1760 (or so), but it could be. Glued a seam, new strings, and replaced the old electronic pick-up with a newer model. He plays it daily.

Both f-holes are missing wings. This one has had a repair, possibly to correct for soundpost-tool damage. Dunno.

Back of the scroll with a rather square bottom. Perhaps a compass layout mark where the spine meets the bottom curve.

The back has a pleasant flame and shows lots of wear, including relatively recent damage such as shoulder rest abrasions, which are also present on the ribs.

The upper treble bout is so worn that wood is even missing through the purfling itself. Evidence of lots of playing time. The button looks as if it may have been broken, or badly crakced at the least.

Both f-holes are missing wings. This one has had a repair, possibly to correct for soundpost-tool damage. Dunno.

The label is very hard to read. It seems to follow the pattern: Egidius Klotz in Mittenwald and der Isar 1760. Could be 1762. Or 1768. Or something else.

Front of the scroll, showing what I think is a very nice patina.

Apparently the volute became separated from the pegbox at some time. The pegbox and scroll have been grafted onto a new neck.

Tuesday, February 5, 2013

Secrets of the Samurai Sword (PBS)

I recently posted a link (on my Facebook page) to a 4-minute video on Samurai swords, the Sword Maker. One of my FB violin-maker friends, Jack Havivi of Tel Aviv, gave me the link to a PBS hour-long documentary, now on YouTube, for Secrets of the Samurai Sword. Both are worth seeing, and naturally the longer PBS version has far more detail.

At one point in the documentary, they refer to "Sword Porn" being the term for the movies most of us in the West have as a basis for knowing anything about the Samurai.

I guess I could diverge and say that many of us seem to get most of our 'knowledge' from movies, but that might be considered cynical, so I won't.

Anyway, in addition to enjoying sword porn, this PBS documentary is also, for us woodworkers, carbon-steel, sharp-edge, traditional-arts, marketing, blacksmith-alchemy, random-effects, waterstone porn. For me, it hit all of those buttons.

The traditional art of steel-making is also explained in scientific terms, this being PBS, but in doing so, they actually show reverence for the randomness and skill in the process, skill that takes decades to develop. Even those older folks with the skill are watching and learning, not quite knowing how it will turn out.

I am currently teaching a few math classes at the local community college. Times being what they are, repair work and sales being down, I took on the classes to keep the cash-flow going. I'm enjoying it, mostly, and it's actually giving me the freedom to turn down some work on really low-end instruments, allowing me to concentrate a bit more on building.

Although the classes are still a traditional lecture format, the homework is done on-line, with those advantages and disadvantages. The students work on their problems, they are graded instantly, and if they want to improve their score, they can re-do the problem. Of course, the 'new' problem is essentially the old problem though generated with different numbers. And that can cause certain issuess -- sometimes the numbers are not all that 'nice'.

Yesterday, several students were complaining that one problem in particular was 'impossible' to do. We took a look at it in class and I agreed that it was quite tough, possibly impossible. Some clamored for more time, an extension on the deadline, and I agreed to give them another day. After class, I had a few students come up and talk about the problem and how they had got it to work out. I tried it at home myself later, and it was tough, but doable.

And then I got thinking to my own college days. I never expected to get all the problems correct. Most of them correct, of course, because I worked hard until I had some understanding, and I was pleasantly surprised on the rare occasions when I did get 100%. What's happened to our expectations?

The contrast between that homework situation and the sword-making struck me. Some of us, myself included, have come to believe that we can always suceed at what we do, that there should be nothing out of our reach, and yet we probably underestimate just how long it takes to get good at something. Students can believe they should be able to get 100% on all their assignments. Violin makers can believe that our instruments should be without any clunkiness, that we'll actually like our varnish, or .... pick your favorite mental poison.

Well, actually customers can be quite demanding on these points, too, but that's just the way it is. You can't take it too seriously.

I found the PBS Samurai video fascinating and inspiring. Take the time to watch it, even if a bit at a time. I think you'll find many pleasant surprises. I'll give away a little teaser. The shape of the blade is a product of, no, that would be wrong to spoil it. I was astonished, though, and it was the point that I decided to write this blog post.

At one point in the documentary, they refer to "Sword Porn" being the term for the movies most of us in the West have as a basis for knowing anything about the Samurai.

I guess I could diverge and say that many of us seem to get most of our 'knowledge' from movies, but that might be considered cynical, so I won't.

Anyway, in addition to enjoying sword porn, this PBS documentary is also, for us woodworkers, carbon-steel, sharp-edge, traditional-arts, marketing, blacksmith-alchemy, random-effects, waterstone porn. For me, it hit all of those buttons.

The traditional art of steel-making is also explained in scientific terms, this being PBS, but in doing so, they actually show reverence for the randomness and skill in the process, skill that takes decades to develop. Even those older folks with the skill are watching and learning, not quite knowing how it will turn out.

I am currently teaching a few math classes at the local community college. Times being what they are, repair work and sales being down, I took on the classes to keep the cash-flow going. I'm enjoying it, mostly, and it's actually giving me the freedom to turn down some work on really low-end instruments, allowing me to concentrate a bit more on building.

Although the classes are still a traditional lecture format, the homework is done on-line, with those advantages and disadvantages. The students work on their problems, they are graded instantly, and if they want to improve their score, they can re-do the problem. Of course, the 'new' problem is essentially the old problem though generated with different numbers. And that can cause certain issuess -- sometimes the numbers are not all that 'nice'.

Yesterday, several students were complaining that one problem in particular was 'impossible' to do. We took a look at it in class and I agreed that it was quite tough, possibly impossible. Some clamored for more time, an extension on the deadline, and I agreed to give them another day. After class, I had a few students come up and talk about the problem and how they had got it to work out. I tried it at home myself later, and it was tough, but doable.

And then I got thinking to my own college days. I never expected to get all the problems correct. Most of them correct, of course, because I worked hard until I had some understanding, and I was pleasantly surprised on the rare occasions when I did get 100%. What's happened to our expectations?

The contrast between that homework situation and the sword-making struck me. Some of us, myself included, have come to believe that we can always suceed at what we do, that there should be nothing out of our reach, and yet we probably underestimate just how long it takes to get good at something. Students can believe they should be able to get 100% on all their assignments. Violin makers can believe that our instruments should be without any clunkiness, that we'll actually like our varnish, or .... pick your favorite mental poison.

Well, actually customers can be quite demanding on these points, too, but that's just the way it is. You can't take it too seriously.

I found the PBS Samurai video fascinating and inspiring. Take the time to watch it, even if a bit at a time. I think you'll find many pleasant surprises. I'll give away a little teaser. The shape of the blade is a product of, no, that would be wrong to spoil it. I was astonished, though, and it was the point that I decided to write this blog post.

Thursday, January 24, 2013

Jim Brown, Violinmaker in Claremont, California.

Jim Brown is the organizer of the Southern California Violin Makers Workshop, which is taught by Michael Darnton. Jim is the fellow who puts everything together, and is even the fellow who picks us students up as we come in to the airport, one-by-one, scattered throughout the day.

Here's a nice 8-minute video on Jim and his own shop.

Breathing Life.

And one of my photos of Jim giving a varnish demo at the 2008 workshop.

Monday, January 14, 2013

John Craft 1975 violin

John Craft was a local maker, local being Nampa, Idaho. This instrument came in for a little repair and set-up work. Here's his 'label' seen through the f-hole.

In spite of some of their eccentricities, violins made back in out-of-the-way places before much information was readily available interest me. I never met John Craft, but I do hear stories of him.

The front of the instrument, showing the general outline. Black-white-black purfling, somewhat pinched corners.

The back was really astounding. A very dynamic finish, it changed readily with the view angle. Here are two shots at different light angles.

The pegbox was somewhat oversized, larger and bulkier than normal. Poorly fit pegs shown here were replaced and the nut was cleaned up. It was too high and had gobs of glue extending out all sides. I don't know whether this was the original set-up or if it had been redone at some time.

Curves of the scroll are a bit clunky. Considering that in 1975 Nampa he probably didn't have much to model it on -- no Internet, no Strad magazine posters -- you do what you do.

The fluting was quite shallow, particularly on the back, with the center ridge nearly disappearing at the heel of the pegbox.

The top seam appeared somewhat open from the outside, though solid. Looking in through the endpin, we could see many diamond-shaped cleats.

Sunday, January 13, 2013

The Color of Age in Wood, part 2

One of my Flickr contacts commented on my photos, posted in this blog yesterday, mentioning the rust marks in the old 2x4s, something she thought might not be pertinent to violins. Her argument that (1) a bathroom wall was periodically very humid, and (2) it contained nails -- unlike violins.

Well, it reminded me of a couple things that many violin makers know, but which might not be common knowledge among normal, non-violin-obsessed folk.

First, the violin (and the viola) actually is subjected to fairly humid conditions. The player is breathing right on top of the instrument, with moist air from the player's nose sending moisture over the top and in the f-holes. I am an amateur fiddler. Our band played a contra dance last night, and as the fiddler, I get quite a work-out. The dance lasts about 2-1/2 hours, and though I'm not playing the entire time, I do probably get a good 45 minutes to an hour of fast playing.

If you watch videos of the really great players, you can often see that they are putting out a lot of energy. And that's just the performance. Imagine the thousands of hours that go into practice.

So that's humidity.

Now about nails. Modern violins are not made with nails. But in the time of the Amati, Guarneri, and Stradivari, they were. The necks were not mortised into the neck block as they are now. They were surface mounted -- a butt joint -- to the ribs, and nailed from behind (drilled first, no doubt) and the plates were installed afterwards. This method is not as strong, in part due to the differential tensions in the strings. Necks could be pulled to the e-string side over time or fail altogether. The neck mortise solved this problem, and nearly all old instruments have had their necks reset, with the addition of wood to make up the difference.

From the National Music Museum at the University of South Dakota, an x-ray of the neck of a tenor viola built by Andrea Guarneri in 1664.

And from a 1693 Stradivari violin, the rust stains from similar nails that have bled out to the surface.

In the Stradivari neck heel, you can also see an extra piece of wood, just above the ebony crown, indicating a neck reset. That is, that slice of wood was added by a later repair person when working on the instrument. The ebony crown is a later addition as well, being put in place to clean up damage done to the button in, say, a neck reset.

You can see the rest of the Guarneri viola here and the rest of the Stradivari violin here.

Some violin makers might try to simulate this sort of aging and some players might look for it because it has the 'right' appearance.

Well, it reminded me of a couple things that many violin makers know, but which might not be common knowledge among normal, non-violin-obsessed folk.

First, the violin (and the viola) actually is subjected to fairly humid conditions. The player is breathing right on top of the instrument, with moist air from the player's nose sending moisture over the top and in the f-holes. I am an amateur fiddler. Our band played a contra dance last night, and as the fiddler, I get quite a work-out. The dance lasts about 2-1/2 hours, and though I'm not playing the entire time, I do probably get a good 45 minutes to an hour of fast playing.

If you watch videos of the really great players, you can often see that they are putting out a lot of energy. And that's just the performance. Imagine the thousands of hours that go into practice.

So that's humidity.

Now about nails. Modern violins are not made with nails. But in the time of the Amati, Guarneri, and Stradivari, they were. The necks were not mortised into the neck block as they are now. They were surface mounted -- a butt joint -- to the ribs, and nailed from behind (drilled first, no doubt) and the plates were installed afterwards. This method is not as strong, in part due to the differential tensions in the strings. Necks could be pulled to the e-string side over time or fail altogether. The neck mortise solved this problem, and nearly all old instruments have had their necks reset, with the addition of wood to make up the difference.

From the National Music Museum at the University of South Dakota, an x-ray of the neck of a tenor viola built by Andrea Guarneri in 1664.

And from a 1693 Stradivari violin, the rust stains from similar nails that have bled out to the surface.

In the Stradivari neck heel, you can also see an extra piece of wood, just above the ebony crown, indicating a neck reset. That is, that slice of wood was added by a later repair person when working on the instrument. The ebony crown is a later addition as well, being put in place to clean up damage done to the button in, say, a neck reset.

You can see the rest of the Guarneri viola here and the rest of the Stradivari violin here.

Some violin makers might try to simulate this sort of aging and some players might look for it because it has the 'right' appearance.

Saturday, January 12, 2013

The Color of Age in Wood

Doing a little bathroom repair, and noticed today something that might apply to violin making, in particular, the antiquing process. Here we have three pieces of wood, probably similar in color originally. Probably similar wood, fir of some sort. Similar to the spruce top of a violin.

The vertical stud is from the 1950s, and most likely has not been exposed to sunlight for much time. The vertical wood on the lower end is from a repair I did about 10 years ago, from the other side of the wall. It's backing for a sheetrock repair. The wood probably had seen some sunlight and was most likely just stuff I had around the shop. The vertical wood at top is new material, bought at the lumber store the other day. Photo taken with no flash, sunlight in the window and incandescent in the room.

Same as above, but with the camera flash on.

The vertical stud is from the 1950s, and most likely has not been exposed to sunlight for much time. The vertical wood on the lower end is from a repair I did about 10 years ago, from the other side of the wall. It's backing for a sheetrock repair. The wood probably had seen some sunlight and was most likely just stuff I had around the shop. The vertical wood at top is new material, bought at the lumber store the other day. Photo taken with no flash, sunlight in the window and incandescent in the room.

Same as above, but with the camera flash on.

Friday, January 11, 2013

Bright idea -- well, 40 watts, which for me is bright.

A non-fiddle-making post, but you have to eat, too.

It’s only taken me, what, a couple decades or so to figure it out......

I use a long rise in my bread making, 24 hours or so. One problem I’ve had is finding a place that is consistently warm over that time period. We turn the heat off at night, and in the winter, it can be 60 degrees F or lower in the kitchen by morning.

Some folks have suggested a warming box -- a box dedicated to keeping the rising dough warm. Simple enough thing. Basically a box and a heat source, such as an incandescent bulb. But I really don’t like kitchen gadgets, those bulky things that are dedicated to a single use, a non-every-day use. Not a solution I’d like.

I’ve also heard of folks using their oven for a warming box. Oven not on, but the light is. The idea being the light provides enough heat. I’ve tried that, and my oven light is not warm enough.

So I decided to buy a light socket, one of those ceramic or plastic fixtures folks use in their utility rooms. Wire a cord on it, with a plug. Attach the base to a short section of 2x4, and I have something I could put in the oven, running the cord out (door closed) and plugged in. I’d have to store the socket-and-board somewhere, but it’s much smaller than a box.

When I got to the hardware store, I found the little socket shown in the photo. About $2. Exactly what I wanted, but didn't know it existed. A 40W bulb and an extension cord complete the concept. Used it last night, and it’s just right. And when I’m done with it, it goes back into a drawer.

My go-to bread recipe is the no-knead version from Jim Lahey's book. You can find a recipe on the New York Times site.

Wednesday, January 2, 2013

Michael Darnton (violin maker) in the News

I've attended the Southern California Violin Makers Workshop every June since 2008. Although the workshop runs for 3 weeks each June, I can only attend for one, occasionally two weeks, each year. I have a frequent conflict with the last week of the workshop as it coincides with the National Old Time Fiddlers Contest in Weiser, Idaho, where we set up shop to tend to instruments and sell a few.

Michael Darnton teaches the Violin Makers Workshop. He's a careful teacher, precise, and probably gets tired of telling me the same thing repeatedly. Eventually, however, I do learn something, so on to the next feature of making. It's also a great opportunity to meet with other makers, see their instruments, and occasionally see some really fine, old Italian fiddles.

Michael was featured recently in his local (Chicago) newspaper. Here's a video clip from that interview (newspaper as in the 21st century sense).

Violin-maker demonstrates his handmade process.

And here is a link to a scanned pdf of the print version.

Endeavor of guesswork.

It's really great for me to see Michael in action, hear his voice, be reminded of this or that part of making.

I also have my own photos from the workshop, links on the year.

2008

2009

2010

2011

2012

Subscribe to:

Posts (Atom)