Student instruments are always problematic. They can suffer a great deal of abuse, unintentional and otherwise. Makers of student instruments -- factories almost always -- in the best of situations have to make something quick, strong, and reasonable. In other cases, they produce outright junk, which can neither be played nor repaired. If you are buying a new violin for $100, for example, you are buying junk.

Parents want their kids to succeed, and they want to save money. When it comes to material goods, however, the parents often think of the cost alone. A child learning to play a musical instrument can be handicapped by an unplayable instrument. That is no value, just cost, even if it is minimal. Learning, however, is the important thing -- that is the value. Any thought of resale value, particularly in a student instrument, pales in comparison to how the child's brain can be developed.

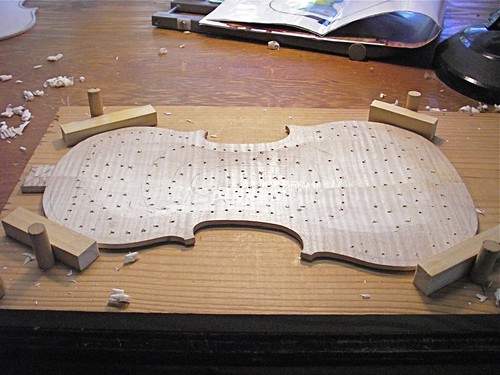

Here is a fractional cello that came into the shop recently. The top had cracked near the tailpiece. I could recognize it as the result of the endblock shrinking -- a very common event on low-end instruments. Preventable with good quality control, but right now that is not important to these makers. They sell instruments easily, so why change?

This one retails for about $1200, not a small amount of money for most parents in this area. And it is not the 'bottom of the barrel' -- I can actually get the top off in a reasonable amount of time with a minimum of damage.

For comparison, though, I thought it might be interesting to show some of the inside details, that don't show up when looking at the shiny new instrument.

Here's the lower corner block on the bass side --

Notice how the block has been roughly split out, and that the c-bout linings, rather than running inside the block, actually stop far short of it. If the glue fails here, these will spring loose, creating quite a buzz.

To show that it's not a fluke, here's the lower treble-side corner block.

It has similar problems. Again, to be fair, these are made very quickly. Any extra time is spent on the outside, the part seen by the customer.

The endblock was just as rough. In this photo, you can see one split-out side, where the drill had been quickly pushed through, probably after the top was glued on. It had a similar fragment, hanging by a thin fiber, on the other side, which I had removed prior to this photo.

Note that the block is loose from the ribs. It is harder to see that the ribs themselves are split, radiating out from the end-pin hole. You can see a linen cleat that I have installed on one of the cracks. This type of damage happens when the cello is dropped on its endpin. A better block, however, might have held.