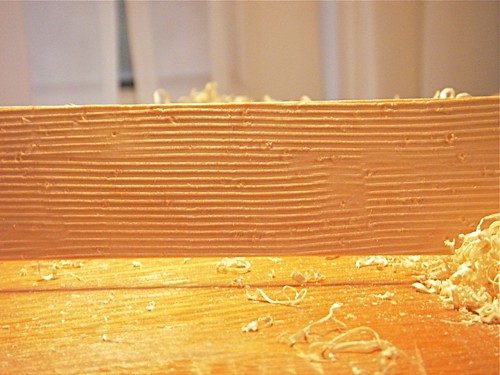

The ground is a commercial shellac, available from hardward and builders supply stores -- Zinnser Bulls-eye, amber. It is 'watered down' with alcohol, in this case, 4 parts shellac to 1 part alcohol. Learned this from Michael Darnton. It's most likely not what was done in the old days, but it does have interesting properties, and the gold color is pleasing. I used it on my previous violin as well.

We have such great sun in Idaho, that I have not yet built a UV-box for varnishing. This time of year, however, we have clouds, wind, rain, snow, varying throughout the day, so I'm hanging the fiddle in the sunlight of our south-facing bedroom window. Pathetic UV, but better than nothing. The black rectangular areas on the back of this fiddle are actually shadows of tape used to plug holes in the screen. Also, our tender herbs, such as this lavender, are inside. Just outside the photo frame are oregano and rosemary. Perhaps the herb fragrance will help with the violin tone. :-)