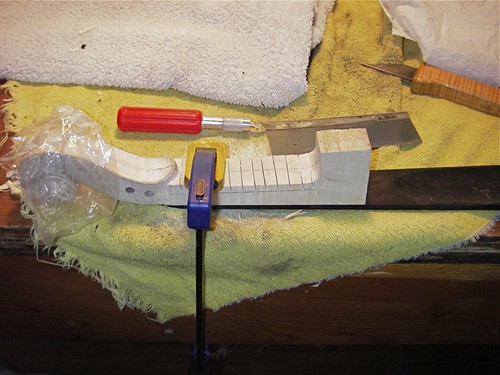

With the neck in the vise, I make a series of cuts to remove wood from the side. Someday I'd like to get a really nice saw, but right now I have a cheap Xacto saw, and it works. The plastic bag is around the scroll to keep it from getting so dirty.

With another couple of cheap tools -- the flat chisels with plastic handles, though well-sharpened, I remove the excess wood from the side. Turn it over and do the same on the other side.

Using calipers and a ruler, I measure the thickness of the neck with the fingerboard. I'll mark a safe line running along the side to show how much wood I can remove. The small grey template between the ruler and neck is to show me both the shapes of the chin and heel (outside edges) as well as the finished thickness of the neck itself (inner arched cutouts).

Clamping the neck in place, I again make a series of cuts to remove some excess wood.

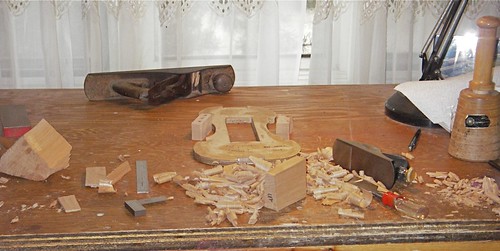

Using rasp and knife, I whittle the neck down to a reasonable, though still oversized, shape. I want to spend good time on the heel end of the neck, getting the angle and lines right before cutting the mortise in the body.