I had a bass in the shop for repair. It had a couple cracks in the heel and a fingerboard that had been reglued in place, or almost in place, with some unknown glue. An amateur repair, the fingerboard had slipped after it was glued, but before the glue had set. Basically a mess. I was able to get the fingerboard off, but did not recognize the glue. It was still plastic, and a dark brown in color. To further complicate matters, a small chunk of the fingerboard had been left glued to the neck prior to the application of this brown glue.

I managed to lift off the small chunk of fingerboard attached to the neck, but none of my known methods of glue removal had much effect on this soft but stubborn glue. In desperation, I tried an old plane I had lying about. I got it several years ago at an antique shop for $20. Hadn't done anything with it, and it was in rough shape.

It actually worked fairly well. I was able to plane the glue from the fingerboard, and then from the neck. And the plane felt pretty nice in my hand.

So, I took the plane apart, cleaned up the blade and the cap, flattened the sole a little bit with a sanding board, and sharpened the blade. This is it in the photo. An old No. 5. It is resting on a piece of poplar about 16 inches long. The shaving is from the first stroke I took with the newly cleaned up plane, a full-length shaving, about 0.011-inch thick -- sometimes it's nice to move a little wood.

I'd been wanting a jack plane, and I just might have something here that works in that capacity.

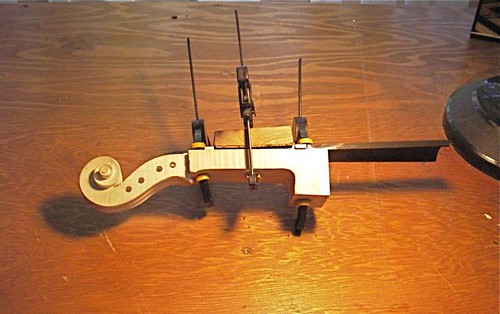

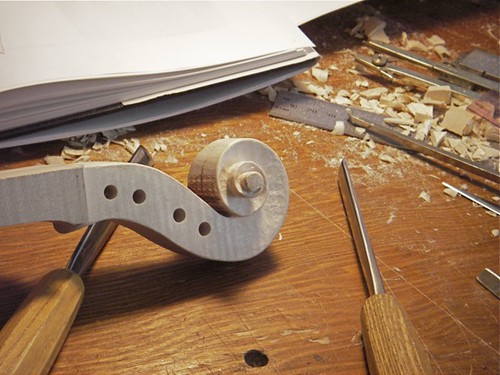

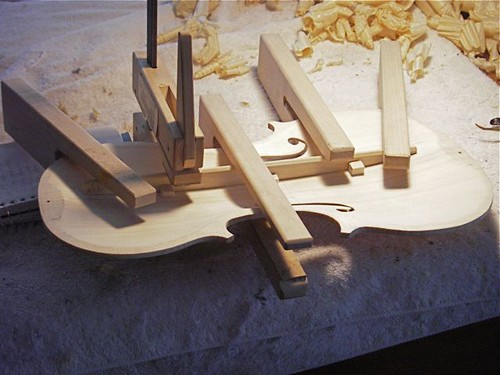

Here's the bass with the neck and fingerboard newly cleaned of plastic glue. I have used hide glue to glue the cracks in the heel, held by the clamp, but will actually resort to a carriage bolt down through the heel to hold it together. On the fingerboard, you might be able to see the small chunk of wood I had to remove from the neck and glue back in; it's about 1/3 the way from the left end, on the lower edge.